5G Thinking from Japan: A Systematic Way to Think and Solve Problems

In today’s fast-paced work environment, challenges can arise at any moment—whether in production quality, customer service, or team management. The critical question becomes: How can we solve these problems accurately and sustainably?

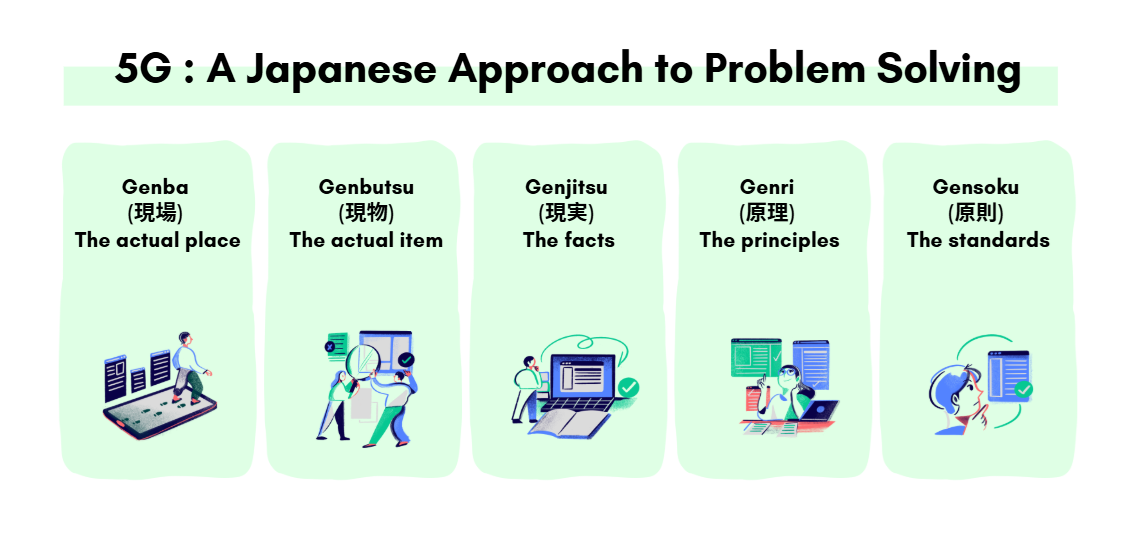

One widely recognized and commonly used methodology in Japan is “5G Thinking”, which consists of Genba, Genbutsu, Genjitsu, Genri, and Gensoku.

5G Thinking originated from Japanese quality and production management systems, particularly in the automotive industry with the Toyota Production System (TPS). This approach emphasizes addressing issues at the root cause rather than applying temporary fixes. The reason Japan values this method is that true problems often lie in small details—details you won’t see unless you go and examine them yourself.

Cr.: https://global.toyota/en/company/vision-and-philosophy/production-system/

The 5 Elements of 5G Thinking

Genba (現場) – The actual place

Genbutsu (現物) – The actual item

Genjitsu (現実) – The facts

Genri (原理) – The principles

Gensoku (原則) – The standards

1. Genba (現場) – The Actual Place

Genba means going to the real site where the problem occurs. Japanese organizations believe that sitting in a meeting room analyzing issues is not enough. To truly understand what is happening, you must see it with your own eyes.

Examples:

If a machine on the production line stops, the supervisor should go directly to the line to observe the situation—rather than rely solely on employee reports.

If customers complain about service, managers should visit the actual location, such as a restaurant, bank branch, or service counter, to see how staff interact and understand the real customer experience.

2. Genbutsu (現物) – The Actual Item

Once at the site, the next step is inspecting the physical objects related to the issue—such as defective parts, malfunctioning machines, or incorrect documents. Examining the actual items ensures that the problem is real and helps accurately identify the cause.

Examples:

In a factory, if a product has defects, the manager should inspect the flawed item to understand what caused it—scratches, incorrect colors, or misaligned parts.

In logistics, if a customer reports damaged parcels, the actual package and packaging materials should be checked, rather than relying only on verbal explanations.

3. Genjitsu (現実) – The Facts

This step focuses on using factual data rather than assumptions or subjective opinions. Facts should come from statistics, measurable evidence, or verifiable records. This reduces bias and ensures decisions are based on reliable information.

Examples:

Collecting data on machine downtime: number of stoppages, duration, and primary causes.

Analyzing real customer complaint records: how many customers faced the same issue and during what time periods the complaints were most frequent.

4. Genri (原理) – The Principles

Effective problem-solving must rely on correct scientific principles or proven theories—not guesses or quick fixes. Using proper principles ensures that solutions are logical, repeatable, and explainable.

Examples:

When machines malfunction, engineering principles are required—such as calculations involving pressure, heat, or component wear.

When customer dissatisfaction arises, companies should rely on Customer Experience (CX) principles, such as response time, politeness, and service workflow.

5. Gensoku (原則) – The Standards

This step involves turning principles into clear rules, work standards, or Standard Operating Procedures (SOPs) to prevent the issue from recurring. This aligns closely with Japan’s Kaizen philosophy, which emphasizes continuous improvement.

Examples:

If products are damaged due to weak packaging, the company should establish new standards for packaging materials.

If data entry errors occur frequently, a double-checking rule should be implemented before approval.

Why 5G Thinking Matters

This mindset helps organizations solve problems systematically and effectively, reducing recurrence and promoting a workplace culture rooted in reality and factual understanding. It also encourages continuous improvement (Kaizen), which is why many Japanese companies—and countless organizations worldwide—apply 5G Thinking to enhance work quality and operational performance.

Cr. : Qualityengineerstuff.com , Sanyosmithailand , hrodthai

Personnel Consultant , We’re Japanese recruitment company in Bangkok. We has been in the business of recruiting Thai and Japanese talent for 30 years.

Companies looking for talent & staffing , please contact us through this form Click

Tel.02-2608454

Email : jobs@personnelconsultant.co.th

Contact & Follow Us